CognitOps Insights

Warehouse Data Optimization: The Future of the DC

Through machine learning and AI, we can gain big data insights and begin to answer questions regarding the past, present, and future. Warehouse databases hold information that can provide visibility into trends, needs, capabilities, forecasts, and prescriptions, and help to streamline distribution center operations.

We just need to unlock it.

Big Warehouse Data: Driving Decisions Across the Supply Chain

Data has become a form of currency within the business environment, and today is often referred to as ‘the new oil’. Data engineering can provide insights into customers, habits, buying patterns, forecasts, new products, and much more. The true test, however, is what is done with all of that information after it has been gathered. How is your company using these insights to drive decisions?

Amazon, Facebook, Google, and Microsoft have collected a combined 1.2 petabytes (1.2 million terabytes) of information, according to allconnect.com. That information feeds their product development, targeted marketing, R&D, and helps them to make key decisions on serving their customers.

So, what does this have to do with logistics? The logistics industry is saturated with data. A majority of companies have a minimum of five systems within their logistics network:

- Enterprise Resource Planning (ERP)

- Order Management System (OMS)

- Warehouse Management System (WMS)

- Warehouse Control Software (WCS)

- Time & Attendance System (T&A)

Some companies employ even more systems, including:

- Transportation Management System (TMS)

- Warehouse Execution System (WES)

- Labor Management System (LMS)

It’s apparent that the logistics industry loves their three-letter acronyms! Each of these systems has databases containing millions of transitions across their lifetime. A majority of companies utilize data sets from the ERP system to drive logistics decisions. There remains tremendous performance benefits potential, however, in the remaining data captured by various supply chain systems.

Contextualizing Warehouse Data with Artificial Intelligence

By leveraging machine learning and AI, we can leverage this data to answer key questions within the distribution center. The databases hold vast amounts of data that can provide visibility into trends, needs, capabilities, forecasts, and more. This helps to answer:

- Do I have enough people for today?

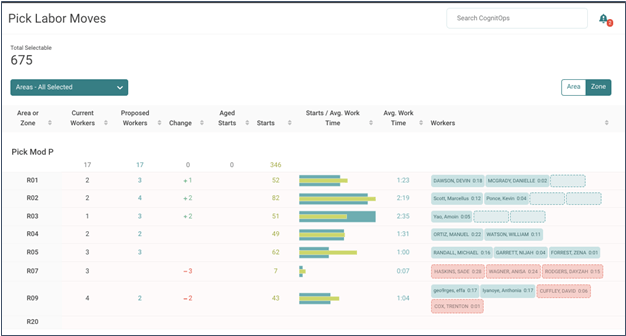

- Where will the work be and who should I staff there to hit my goal?

- Where are my orders getting stuck within the processes?

- What replenishments will block orders from being shipped?

- What automation do I need to turn on or add to my operation to handle the goal?

- What is my projected overtime today or can I offer to send employees home?

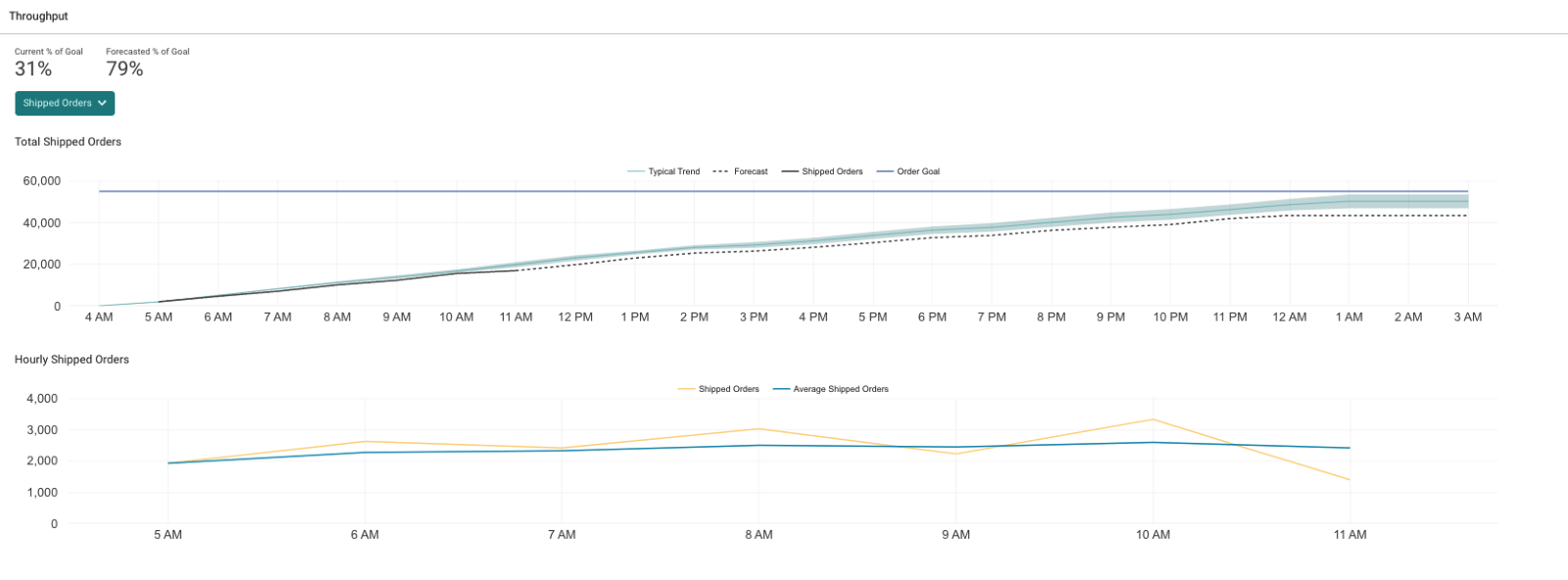

CognitOps Align: Order Forecast

CognitOps Align: Real-time operations handling

Empowering People with Predictive Recommendations

CognitOps has tapped these warehouse databases in order to provide our clients with answers to these questions and more. By accessing and analyzing warehouse data, displaying that data in a meaningful way, and most importantly, providing prescriptions based on the data for the execution of operations, we can help drive warehouse efficiency.

Having this information at the operators’ fingertips will enable them to make labor decisions sooner. The results include better use of employee time, improvements to cycle-time, and streamlined order flow.

Our goal is simple, harness the existing system stack to provide leadership with advanced tools to optimize their operations!

Empower your decision-making with AI-powered insights from CognitOps. Get in touch here.