CognitOps Insights

Improve Warehouse Operations with Real Visibility

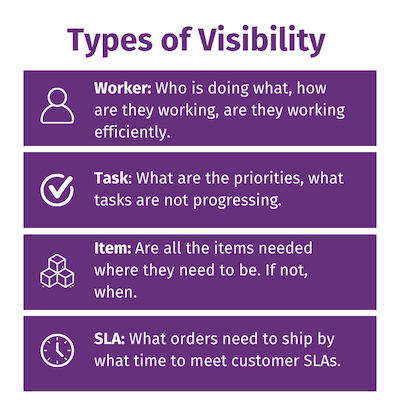

We all know that you can’t fix what you can’t measure. In fact, if you can’t measure it, you can’t even really know if it needs to be fixed. When it comes to warehouse operations, without visibility into every corner and across the facility, how do you know how well you’re operating in one area vs another? Do you know when you’re out of balance or when one area of your warehouse is outpacing another?

A warehouse is an integrated machine where every zone and department must work in concert to achieve the optimal result. When operations aren’t balanced, costs can rise, customer SLAs could be missed, and overall KPIs could suffer. Real visibility is critical to ensuring that your warehouse operations continue to run smoothly.

Signs of Warehouse Operations Dysfunction

Today, many warehouses operate with the see/fix method — similar to how some people treat their cars. If you have a check engine light, it’s probably a sign you have a problem, so you take the car into the shop. It’s the same in the warehouse: supervisors realize there’s a problem when the signs become obvious:

- A bunch of late picks in a certain area.

- Too many boxes piled up on the dock.

- A long list of “outs” in inventory.

Many are willing to live with the process of waiting for signs to arise as the cost of doing business in a warehouse. In a small operation, this can work with supervisors who have enough industry experience to identify the probable cause and make the adjustments needed – after the problem has become obvious.

But with cars it’s a bad idea to wait until the engine is making a clunking noise or spewing exhaust to get it checked out. It can be just as detrimental to wait in a warehouse. When processes fall behind, companies often solve the problem by throwing more resources at it. That can mean workers pulled from a different area or expensive overtime. Just like regular maintenance is crucial to preventing bigger auto issues – those 5,000 mile oil changes are important – keeping your warehouse on track is always less costly than trying to catch up.

The key to staying ahead of issues is real visibility into warehouse operations.

Today, many warehouse supervisors might go into their WMS and see all the open tasks listed for a coming wave. However, those tasks are not organized by area, type of work, order, or due date. That means supervisors are sifting through a long, detailed list of line items to try to understand where the work is and what needs to be done.

While some might call this “visibility” in the sense that it is tracked and available, without structure, analytics, and insight, it’s no better than operating in the dark.

Siloed vs. Integrated Warehouse Operations Visibility

Even with those reporting limitations, most supervisors in each department have a general idea of what they need to do. But this same focus on their own department can lead to a siloed viewpoint. For example, a picking manager over a specific part of a department might try to hold onto as much labor as he possibly can so that he can ensure his team gets the work done at the rate he’s responsible for.

Even with those reporting limitations, most supervisors in each department have a general idea of what they need to do. But this same focus on their own department can lead to a siloed viewpoint. For example, a picking manager over a specific part of a department might try to hold onto as much labor as he possibly can so that he can ensure his team gets the work done at the rate he’s responsible for.

But the truth is that each zone of a distribution center can’t really operate in a silo. Inventory comes in, moves from area to area, and then goes out. Having the right people and the right inventory in the right spot for the available work is vital to a smooth, efficient operation.

Wave-based warehouses, for example, need to make sure the inventory is in the right location so that the picks can be completed. Seeing the progress of each wave across these departments can quickly show if replenishment is falling behind, which puts them at risk of shorted picks or cancellations, which can ultimately negatively impact the customer.

A single monitoring platform that provides views into different processes, like facility wave completion or inventory and pick progress, enables supervisors to quickly identify when areas are out of sync – when picking is too far ahead, or replenishment is too far behind, for example. They can then adjust to avoid potential short picks. There is a clear labor cost benefit to having the necessary inventory in the right place the first time, preventing the need for multiple trips or chasing the items down.

Value Through Visibility with CognitOps

We pull together all the information from various areas, zones, and functions to provide a real-time representation of the cross-departmental workflow, in a single platform. This benefits area supervisors as well as the facility manager. The manager can leverage all this insight into time-sensitive decision-making, ensuring that resources are balanced across the facility to ensure smooth operations.

We pull together all the information from various areas, zones, and functions to provide a real-time representation of the cross-departmental workflow, in a single platform. This benefits area supervisors as well as the facility manager. The manager can leverage all this insight into time-sensitive decision-making, ensuring that resources are balanced across the facility to ensure smooth operations.

We know operators are inundated from all sides with alerts, radios, email, and a multitude of different systems holding different critical information. From the conveyor to HMI to the WMS, no one has time to dig through all the manual information in all the different tools, pull that data into Excel, and run a macro to understand what’s happening.

Having all that data integrated into one view means there’s no need to dig through multiple screens in a manual and time-consuming attempt to discover the current state of the warehouse. Or, potentially worse, wait for someone else to do all that work and send it out only a few times a day so that you can know what was going on in your warehouse and what you need to fix before the end of the day.

Returning to our car metaphor, you can think of CognitOps as the mechanic with the tools to analyze all the faults and dig deeper than you can see at a glance. We give you a clear view into what’s going on under the hood of your facility, deliver aggregated data in real time, and guide you to the areas you need to focus on.

Preventive Measurement and Proactive Adjustments

Our customers already leverage the granular and wide-ranging visibility CognitOps Align provides to measure, learn, and improve across their operations:

- Employee Performance – Real-time visibility into employee performance gives supervisors and leads the ability to coach in the moment. CognitOps generates real-time rates while measuring utilization and efficiency.

- Historical Reporting – Your data is stored in perpetuity. CognitOps historical reporting standardizes your reporting needs while reducing overhead required to generate and maintain reports.

- Department Start Times – During a scheduled delayed start the team noticed that the department rates actually increased. The team got the same amount of work done with less hours because more work was ready when they arrived. Ultimately, this led to the decision to delay start time to help maintain that increase in rate.

- Zone Performance – The team was able to identify that one zone had a higher rate than an adjacent zone. The lower-performing zone has a longer pick path, but with this information available to them, the team can adjust to account for this performance difference.

- Work Forecasting – Monitoring and comparing CognitOps forecasts to internal forecasts has shown that CognitOps forecasting is just as or more accurate than internal forecasting. This has reduced overhead for collecting data and creating forecasts.

CognitOps’s goal is to remove the detrimental subjectivity in warehouse measurement. When every warehouse measures its KPIs differently, reports inconsistently and defines terms individually, you either can’t trust the metrics or you spend too much time rationalizing them.

We are working toward stable standards, global visibility, and data-driven insights. We want to make the warehouse and the network a level playing field where measurements and analytics are consistent across the board, enabling operations leaders to truly see, understand, and optimize their distribution networks.