Insight: Feature Development

Case Study: Optimizing Warehouse Shift Handoff

In this warehouse optimization case study we’ll walk through the challenges distribution centers face at the start of each shift and how they can tackle them by optimizing warehouse shift handoff to get to peak performance faster.

Challenge: Shift handoff disruption

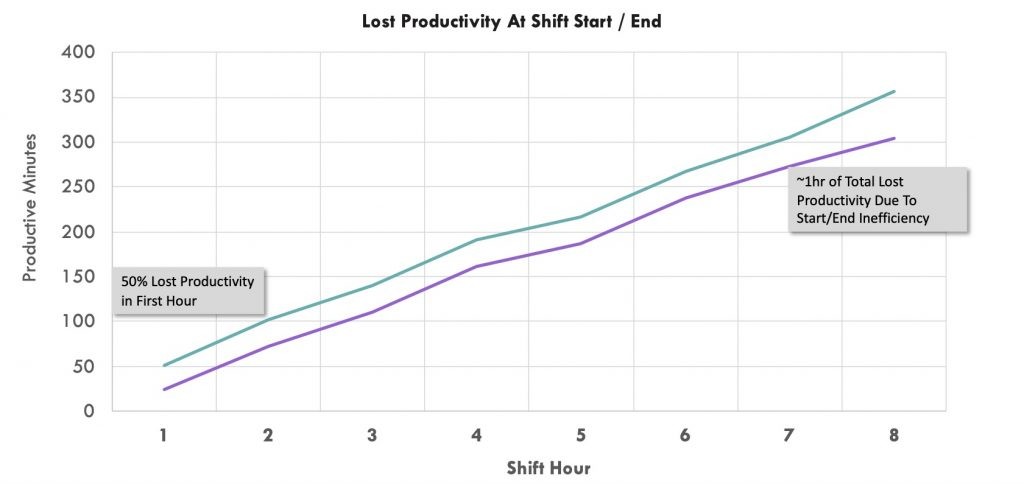

Oftentimes, the first 30 minutes at the start of a shift is spent priming work, instead of actually doing it. That time is impossible to make up. Our experience shows that, on average, the first hour of a shift is between 15% and 30% less effective than all other hours of the day.

The solution may seem obvious: at the end of each shift, leave the facility in a state where the next crew can get off to a running start. Defining, and then achieving that state, however, is not so obvious. Distribution centers are complicated. Labor moves and other operational adjustments don’t happen in a vacuum, and making reliable predictions requires a holistic view of the warehouse.

If shift supervisors rely on daily – or worse, historical – averages for work rates, the accuracy with which they can forecast even an hour into the future is limited. Moreover, immutable features, like the order pool composition and the amount and characteristics of work in process, are outside of the supervisor’s control, and these features interact with operational features, like labor allocations, in complicated ways.

Solution: Shift Handoff Optimization

So how does CognitOps Align make its shift handoff recommendations? First, we collect data that represents the current state of the distribution center. Then we look at all of the possible adjustments a shift supervisor could make to the way the building is operating, forming a prediction space covering hundreds of different possibilities.

We then leverage all of the historical data we have collected to make predictions over the entire space of possibilities, factoring in any penalties associated with changing the warehouse from its current state. Based on the facility’s key performance metrics, we recommend changes that are most likely to leave the building in a state most closely matching the desired starting conditions for the next shift.

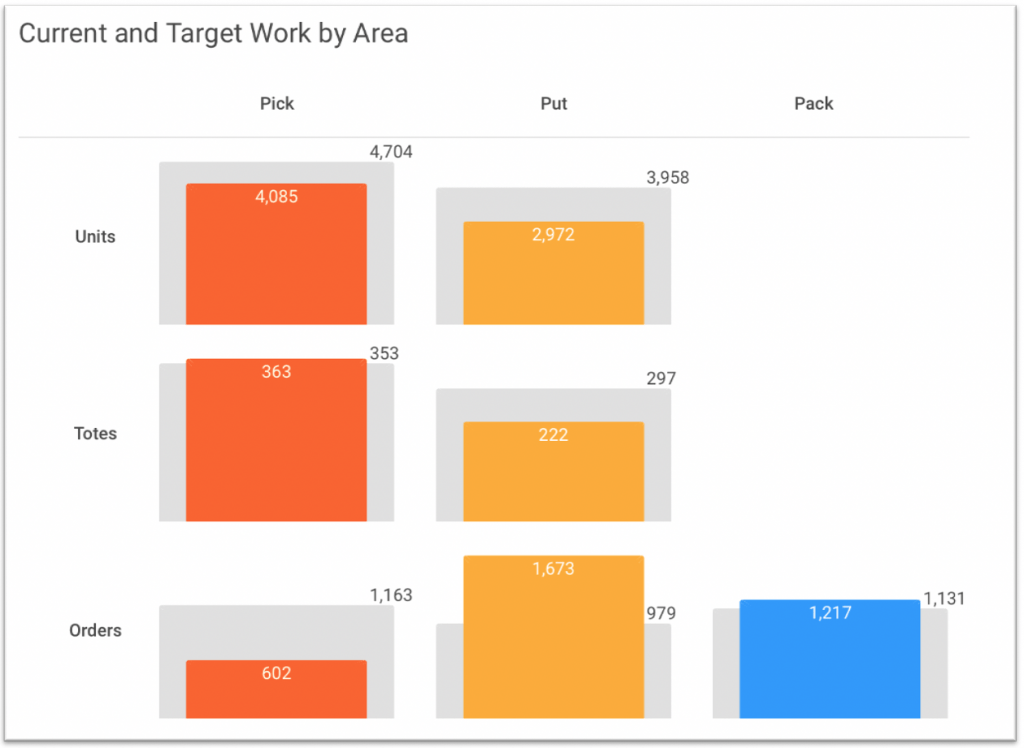

CognitOps ShiftLaunch provides targets at all functional areas across multiple dimensions.

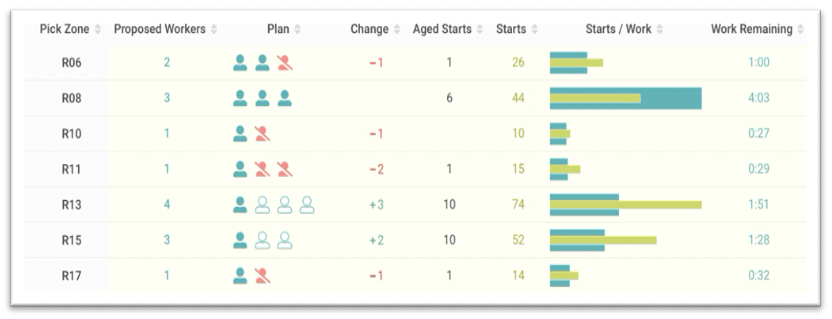

CognitOps platform provides staffing guidance by pick zone to achieve ShiftLaunch targets

These recommendations serve as a set of targets for the operator to leave the DC fully primed and ready for the next shift. When activated, ShiftLaunch provides the leader with the work release, labor allocation, and equipment activation guidance to achieve a smooth handoff to the next shift.

Result: Increase DC Performance 15%

The first thirty minutes of a shift sets the tone for the next several hours. If operators can ensure the DC lets the next shift can hit the ground running, through clearly defined targets and prescriptive guidance, then that shift will reach peak productivity faster. Our internal analysis shows this lift can reach 15% of DC performance, when including loss during the close-out of shift.

ShiftLaunch is a powerful tool in the CognitOps Align platform. It provides operations managers with visibility, guidance and support to make the best decisions for their businesses.

Learn More

CognitOps is a cloud-based warehouse optimization solution.

To learn more about CognitOps ShiftLaunch on the Align platform, please reach out here – we look forward to talking to you.